The Future of 3D Printing: Trends to Watch

Introduction to 3D Printing Advancements

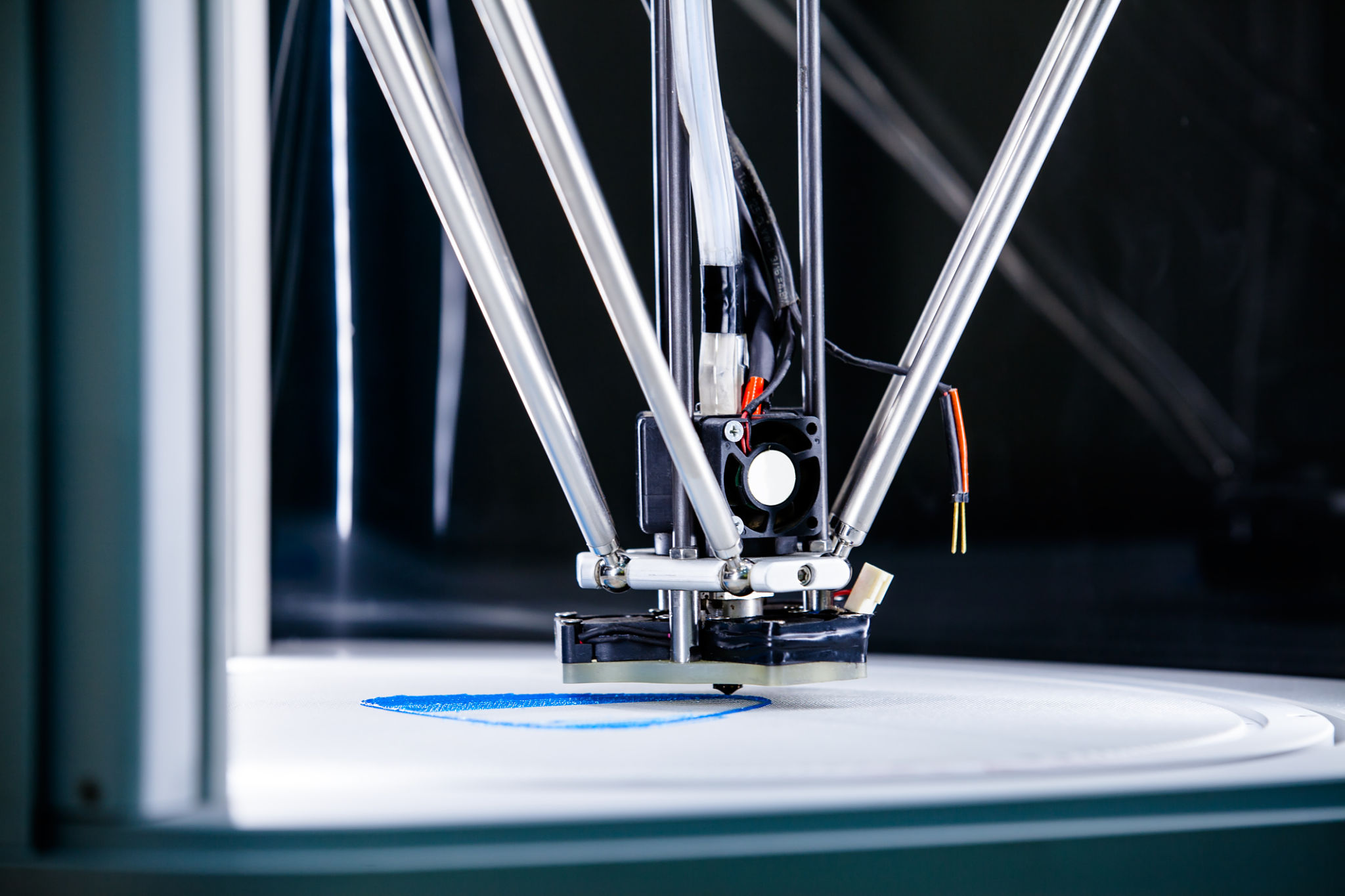

The world of 3D printing is evolving rapidly, transforming industries and pushing the boundaries of what's possible. As we move into the future, several trends are emerging that promise to shape the trajectory of this innovative technology. From advancements in materials to the democratization of production, 3D printing is set to revolutionize how we create and consume goods.

Materials and Sustainability

One of the most significant trends in 3D printing is the development of new materials. Traditionally, 3D printing has been limited to plastics and polymers, but advances in material science are expanding the possibilities. Metals, ceramics, and even organic materials are now being used to print a wide array of products. This expansion not only enhances the versatility of 3D printing but also opens up new applications in industries like healthcare and aerospace.

Sustainability is also becoming a crucial focus. As concerns about environmental impact grow, the use of recyclable and biodegradable materials in 3D printing is gaining traction. Companies are increasingly striving to minimize waste by recycling materials and adopting more sustainable production methods.

The Rise of Customization

3D printing offers unparalleled opportunities for customization, allowing businesses and consumers to create unique, tailor-made products. This capability is particularly valuable in sectors like fashion, where personalized items can be produced on demand. With the rise of digital design tools, consumers can now participate directly in the design process, making customization more accessible than ever.

Integration with Other Technologies

As 3D printing technology matures, its integration with other emerging technologies is becoming more prevalent. For instance, combining 3D printing with artificial intelligence allows for more efficient design processes and optimized production. AI can analyze data to suggest design improvements or material choices, enhancing both productivity and product quality.

Similarly, the Internet of Things (IoT) is playing a role in advancing 3D printing capabilities. IoT devices can monitor and control 3D printers remotely, providing real-time data and enhancing machine learning capabilities for smarter manufacturing processes.

Impact on Supply Chains

The potential for 3D printing to disrupt traditional supply chains is profound. By enabling localized production, businesses can reduce their reliance on global supply chains, lowering transportation costs and lead times. This shift towards decentralized manufacturing can also lead to more resilient operations, as companies become less vulnerable to international disruptions.

Moreover, 3D printing allows for on-demand production, reducing the need for large inventories and minimizing waste. This flexibility is particularly beneficial in industries where market demands can fluctuate rapidly.

Conclusion: Embracing the Future

The future of 3D printing is bright, with trends indicating a move towards more sustainable, customized, and integrated manufacturing processes. As technology continues to advance, it will undoubtedly open up new possibilities and reshape industries across the globe. Businesses that embrace these trends will be well-positioned to lead in an increasingly competitive market.

As we look ahead, it's clear that 3D printing will play a critical role in shaping the future of manufacturing, offering innovative solutions that cater to both global challenges and consumer demands.