Choosing Between 3D Printing and Traditional Manufacturing: A Comprehensive Comparison

Introduction to Manufacturing Methods

In today's rapidly evolving industrial landscape, choosing the right manufacturing method is crucial for businesses aiming to balance cost, efficiency, and innovation. 3D printing and traditional manufacturing are two prominent methods, each with its own set of advantages and limitations. Understanding these differences can help businesses make informed decisions that align with their production goals.

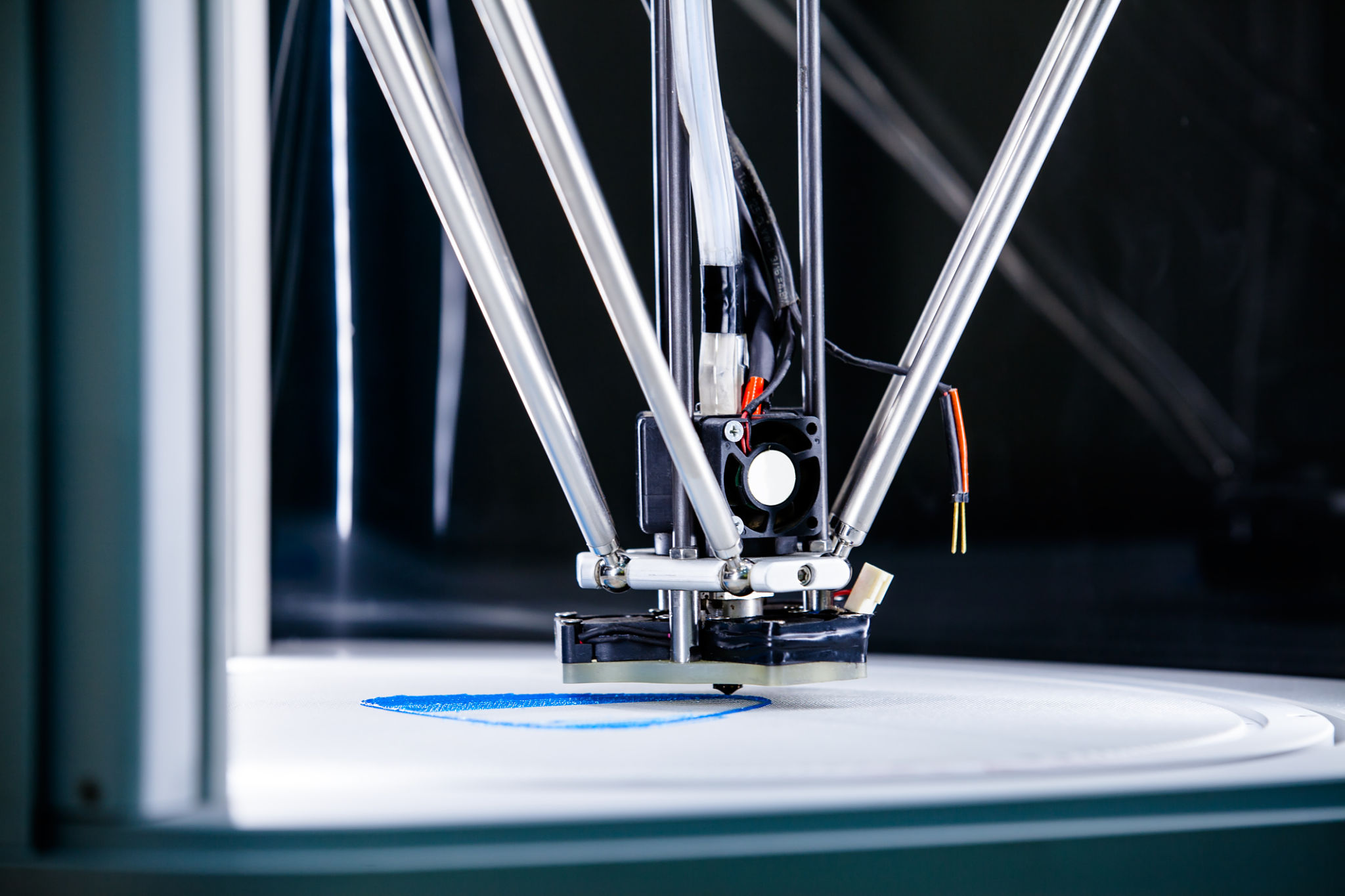

The Basics of 3D Printing

3D printing, also known as additive manufacturing, involves creating objects layer by layer from a digital model. This method offers unparalleled flexibility, allowing for the production of complex geometries that are often impossible with traditional techniques. It is particularly beneficial for prototyping, as it enables rapid iteration and customization without the need for specialized tooling.

Benefits of 3D Printing

The primary advantages of 3D printing include reduced material waste, as the process only uses material where necessary. It also allows for quick turnaround times from design to production, making it ideal for small batches and bespoke designs. Furthermore, 3D printing can reduce the need for assembly, as complex structures can be printed in one piece.

Understanding Traditional Manufacturing

Traditional manufacturing encompasses a range of processes like injection molding, machining, and casting. These methods are well-suited for large-scale production due to their ability to produce parts consistently and cost-effectively once initial tooling is established. Traditional techniques are often preferred when high volumes and uniformity are essential.

Advantages of Traditional Manufacturing

One of the most significant benefits of traditional manufacturing is its ability to produce high-quality parts at scale. Additionally, the materials used in these processes are generally well-understood, offering predictable performance in various applications. For industries where regulatory compliance is crucial, traditional methods provide a level of assurance and reliability that can be critical.

Cost Considerations

The financial implications of choosing between 3D printing and traditional manufacturing can vary significantly depending on the scope and scale of production. Generally, 3D printing has lower upfront costs, as it eliminates the need for expensive molds or tools. However, per-unit costs may be higher compared to traditional methods when producing large quantities.

Scalability and Production Volume

When considering scalability, traditional manufacturing typically excels in high-volume production scenarios. Once the initial setup is complete, the cost per part decreases significantly as production scales up. Conversely, 3D printing is more scalable for low to medium volumes where customization and flexibility are more important than unit cost.

Conclusion: Making the Right Choice

Deciding between 3D printing and traditional manufacturing depends on various factors such as design complexity, production volume, and budget constraints. For companies looking to innovate with complex designs or produce limited-run items quickly, 3D printing offers substantial advantages. On the other hand, when consistency and scale are paramount, traditional manufacturing remains a reliable choice.

Ultimately, the choice between these two methods should align with your specific production needs and strategic objectives. By understanding the strengths and limitations of each approach, businesses can make well-informed decisions that optimize both efficiency and innovation in their manufacturing processes.